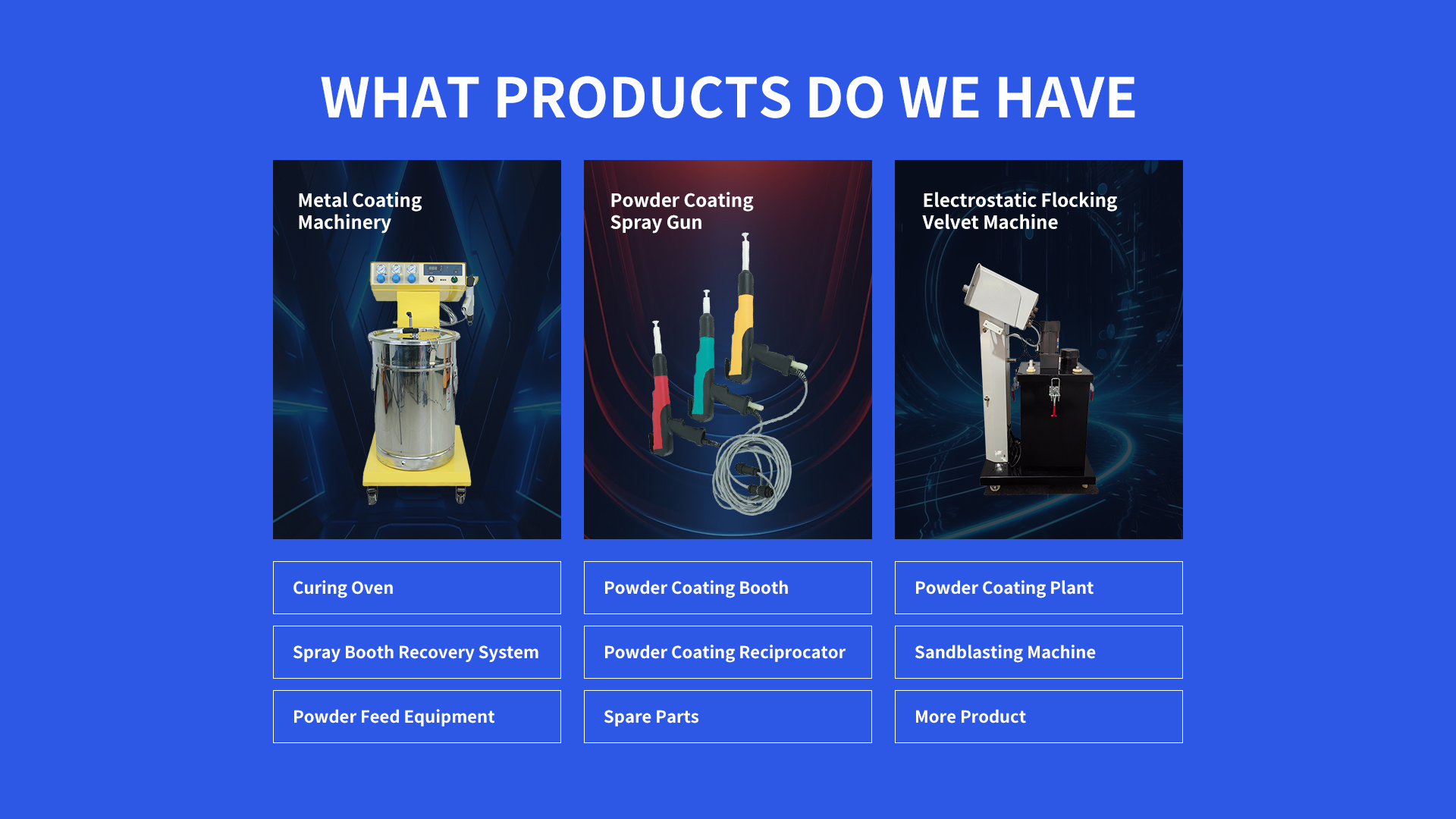

1. Powder Spray Machine Overview and Structural Components

A Powder Spray Machine applies dry coating materials electrostatically to metal surfaces. Key components include a powder hopper, electrostatic spray gun (corona or tribo-charging), high-voltage generator, control interface, and recovery system. Industrial models integrate PLC automation for precision, while compact units suit small workshops. The recovery system filters overspray, achieving 95% material reuse, crucial for cost efficiency.

2. Key Industrial Applications of Powder Spray Machines

These machines excel in automotive (engine parts, wheels), aerospace (aircraft components), and construction (steel beams). They also coat appliances, medical tools, and agricultural machinery. UV-resistant finishes meet outdoor durability standards, while FDA-compliant powders ensure safety in food-processing equipment.

3. Powder Spray Machine Pricing and Cost Factors

Manual spray guns start at 500forSMEs.Semi−automaticsystemsrangefrom2,000–15,000,idealformid−scaleproduction.Fullyautomatedlineswithroboticarmsexceed50,000, targeting high-volume manufacturers. Energy efficiency, brand reputation (e.g., Wagner, Nordson), and IoT capabilities influence long-term ROI.

4. Best Practices for Operating Powder Spray Machines

Surface Prep: Degrease substrates and apply phosphate conversion coatings.

Spray Settings: Adjust voltage (30–90 kV) and airflow (0.5–1.5 bar) for uniform coverage.

Gun Technique: Maintain 8–12-inch distance; use overlapping strokes at 20–40 cm/s speed.

Curing: Bake at 180–200°C for 10–15 minutes; monitor with infrared sensors.

5. How to Select the Right Powder Spray Machine

Evaluate:

Throughput: 10–100 kg/hour based on production needs.

Material Compatibility: Epoxy, polyester, or hybrid powders.

Automation: 6-axis robots for complex parts vs. manual guns for prototypes.

Certifications: CE, OSHA, and ISO 9001 compliance.

6. Safety Protocols for Powder Spray Machine Operations

PPE: Wear NIOSH-approved respirators and anti-static clothing.

Ventilation: Install explosion-proof exhaust systems to minimize dust ignition risks.

Grounding: Ensure <1 ohm resistance to prevent electrostatic discharge.

Fire Safety: Keep Class D extinguishers near powder storage areas.

7. Design Efficiency in Modern Powder Spray Machines

Advanced models feature energy-saving modes (30% less power), modular nozzles for quick swaps, and IoT-enabled diagnostics to predict maintenance needs. Ergonomic grips reduce operator fatigue, while compact designs optimize floor space.

8. FAQs on Powder Spray Machine Performance

Q: How does electrostatic charging improve powder adhesion?

A: Charged particles cling to grounded surfaces, ensuring even coverage and reducing waste.

Q: Can powder spray machines coat non-conductive materials?

A: Yes, using UV-cured powders or conductive primers for plastics/composites.

Q: What maintenance extends a powder spray machine’s lifespan?

A: Clean filters daily, replace nozzles quarterly, and recalibrate voltage monthly.

Q: Are powder-coated finishes environmentally friendly?

A: Zero VOCs and 95% material reuse align with EPA and REACH regulations.

Q: How to minimize orange peel texture in coatings?

A: Optimize gun speed, powder particle size (15–50 μm), and curing temperature.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com